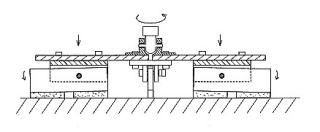

Balance type

Super High Speed Diamond Full Automatic

Polishing Machine

JP.PAT, No5608310.

Feature

① For super high speed polishing, the side movemet speed change

to 7.5m/min, the front-backmovementspeed

to 3.5m/min.

② The high efficiency polishing is achieved by the high movement

speed and the high speed rotation .

③ The high speed polishing is realized by the quiet new mechanics

of polishing wheel, the balance type

polishingwheel.which is able to keep the completely plane

surface from the beginnig of use to the finish.

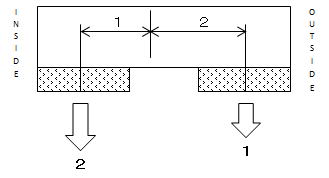

④ This balance type polishing wheels can achieve the equally wearing between the outside and the inside.

If the position of pin become to outside , outside tip be

passed by big pressure, if the position of pin

becometo inside, inside tip be pressed by big pressure .

( This principle prevent from the status of becoming inside

higher tip )

⑤ The polishing cost become 1/3 lower and the polishing efficency become 3times higher than the stone

bricks polishing .

Feature

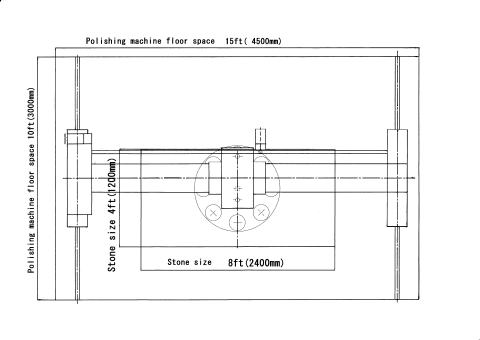

| Polishing Area | 8feet (w)×5.5feet(d) |

| Polishing wheel | Metal:#80、#150、#300 Resin:#500、#1000、#2000、 Buff |

| Motor | Main spinflr 5.5KW、left-right 0.4KW、forward-rearward 0.4KW |

| Method of press | Compressed air pressure |

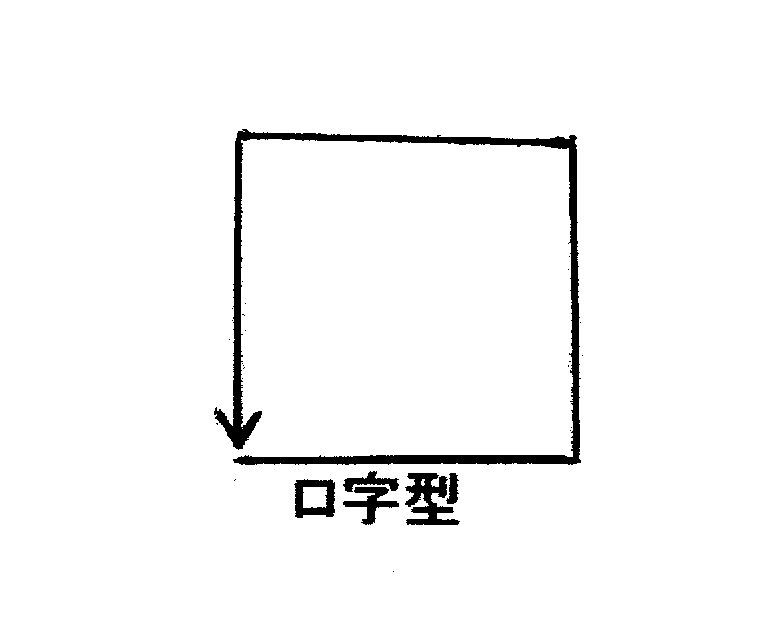

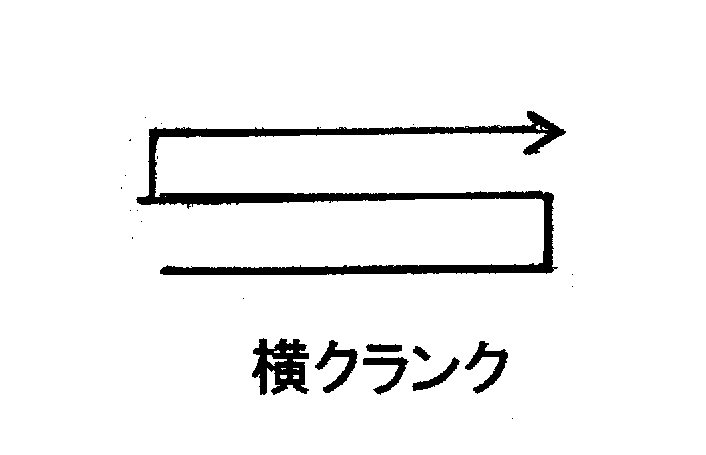

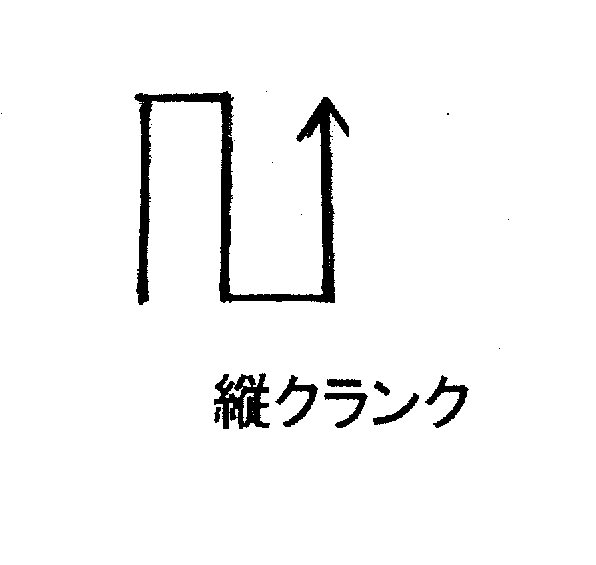

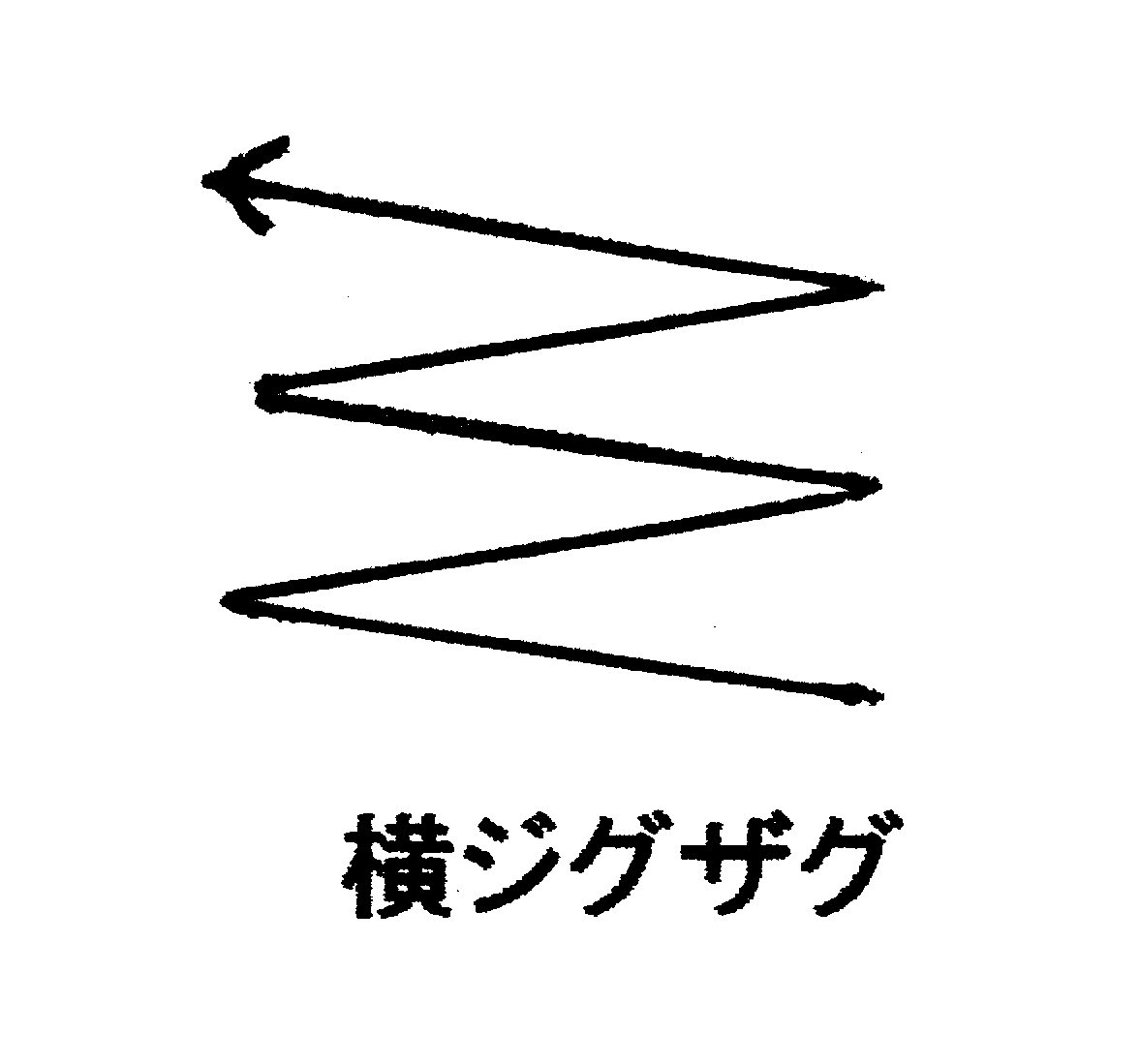

| ロform | Side crank | Vertical crank | Side jigzag | Vertical jigzaj | Jigzag |

|

|

|

|

|

|

| It can polish 10mins for 1feet x 2feet back granite |

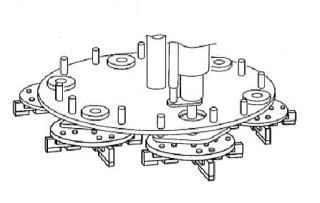

Balance type Polishing wheel (12inches, metal ) |

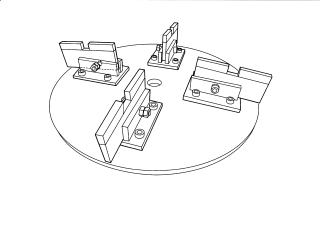

BalancetypePolishingwheel (12inches,resin) |

| |

|

|

| There are 8 polishing wheels at the disk wheel under the machine.Accordingly the wheels move under the main shaft that rotate and start polishing . |

|

| The pin shift from the center to inside , the pin supports the polishing tip and enable movement of the polishing tip to behave as seesaw. |

|

| The polising tip are supported by the pin which position is not center but is shifted to inside. So it can be change the pressure for polishing between inside and outside. |

|

| The moving distance of polishing tip is very different between the inside and outside.At the moving distance of one rotation , the outside tip moves longer than inside tip.Longer movement - rotation of the outside tip cause higher wearing than inside tip so the status of inside tip higher occur.The accumulated puressure( puressure difference ) from spindle is divided into outside and inside by the pin of balance board.That helps to change the puressure to the tip of inside or outside, according to the pin position. |

|

| The diamond polishing machine achieve the smallest floor space and the maximum polishing efficency.It can polish 33sq・ft/h, this is 3times bigger thank bricks. And bricks polishing machine need 15ft and 66ft space. It may be 6times bigger space . |

| All of diamond tips on the polishing wheel touches the stone surface and work / polish by the balance function.The polishing time is reduced and polishing speed is increased usually the working tip is about only one third on the conventional polishing wheel. |

| Top page |

| About Company |

| Contact Information |

| Product Information |